Liquid

Liquids

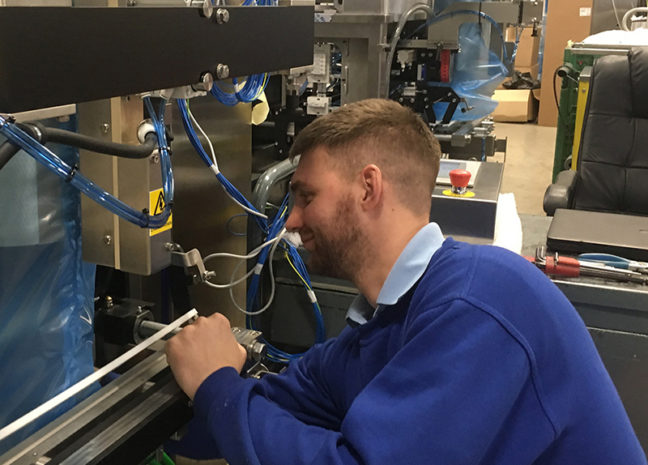

GIC has been designing, installing, and servicing vertical form fill and seal packaging machines for four decades. UK-made to the highest standards, GIC’s machines play an essential role in some of the country’s largest suppliers of liquid products.

GIC machines are designed and built in Gainsborough to exacting standards. We are a gold-level partner in the Rockwell Automation PartnerNetwork™ programme, and all our component suppliers are hand-picked for quality and reliability.

Irrespective of whether you are packing soups, sauces, marinades or liquid based chemicals we can design a machine customised to your requirements. We back up our engineering excellence with operator training and comprehensive service and maintenance plans to ensurehassle-free ownership.

Our vertical form fill and seal machines offer the optimum combination of effectiveness, reliability and low cost of ownership backed by first-class technical and servicing support.

Download Brochure

Key Considerations

When packing liquids with a vertical form fill and seal (VFFS) machine, several factors need to be considered to ensure efficient and effective packaging.

We need to understand the product and its characteristics, including the required temperature at the point of packing, the size of the particulates within the liquid and its viscosity.

The speed of the transport cycle may have to match the pump dosing to avoid contamination of the following seal area. The viscosity of the liquid can vary a lot, with some flowing more quickly than others impacting the speed of the dosing.

Ensuring the pump operates in synergy with the bag forming is crucial. The liquid can splash onto the side of the pack if the pump is too fast. If the pump is too slow, valuable time will be lost, possibly leading to seal contamination. We are experienced in working with pump manufacturers to ensure the optimum design and seamless integration with our vertical form fill and seal machines.

Our experience tells us there is no ‘off the shelf’ solution for packing liquids. Every project needs a bespoke solution.

GIC work closely our Customers to find the correct film specifications. Several factors must be considered when deciding which type of film is best for the application, including sealability, puncture resistance, the ability to take the product’s weight when running a hot fill, and light infiltration.

Most liquids are packaged in a laminate film, with nylon, PET or OPP on the outside and polyethylene on the inside. GIC are also working with various film manufacturers to provide solutions on our machinery for recyclable, biodegradable and other sustainable films.

Most liquids are packed in pillow packs, but at GIC, we can also configure our machine type to pack into a piping bag, which makes releasing the liquid incredibly easy and accurate – you just cut one corner off the trapezoidal pack and squeeze.

As most companies working with liquids tend to do lots of short runs, of around two to three hours, they are changing the forming set regularly and will require several forming sets, one for each pack width. The ease and speed at which the forming set can be removed and installed is particularly important, as is the availability of stainless steel forming sets for hygiene, which can be removed without using tools.

For Liquids

GIC CUB

- Maximum pack size150mm

- Maximum speed60 packs per minute

- Pack formatsPillow, Gusset, Block Bottom

- Packaging materialsAll suitable heat-sealable materials, including laminates and polyethylenes. Optional impulse sealing

GIC 200

- Maximum pack size250mm

- Maximum speed50 packs per minute

- Pack formatsPillow, Gusset, Block Bottom, Euroslot, Carry Handle, Punch Hole

- Packaging materialsAll suitable heat-sealable materials, including laminates and polyethylenes. Optional impulse sealing

GIC 400

- Maximum pack size400mm

- Maximum speed50 packs per minute

- Pack formatsPillow, Gusset, Block Bottom, Euroslot, Carry Handle, Punch Hole

- Packaging materialsAll suitable heat-sealable materials, including laminates and polyethylenes. Optional impulse sealing

GIC 2100

- Maximum pack size250mm & 400mm

- Maximum speed70 packs per minute

- Pack formatsPillow, Gusset, Block Bottom

- Packaging materialsAll suitable heat-sealable materials, including laminates and polyethylenes. Optional impulse sealing

GIC 4100

- Maximum pack size250mm & 400mm

- Maximum speed70 packs per minute

- Pack formatsPillow, Gusset, Block Bottom

- Packaging materialsAll suitable heat-sealable materials, including laminates and polyethylenes. Optional impulse sealing

Free Site Appraisals

Irrespective of whether or not you currently rely on GIC vertical form fill and seal packaging machinery to keep your production line flowing efficiently, we offer free site appraisals.

Our experienced engineers will visit your facility and provide an accurate overview of the current condition of your packaging machinery, service and maintenance requirements, available software and hardware upgrades and opportunities to improve operating efficiency.

To request your free site appraisal, email us or call +44 (0) 1427 611885