Frozen Food

Frozen Foods

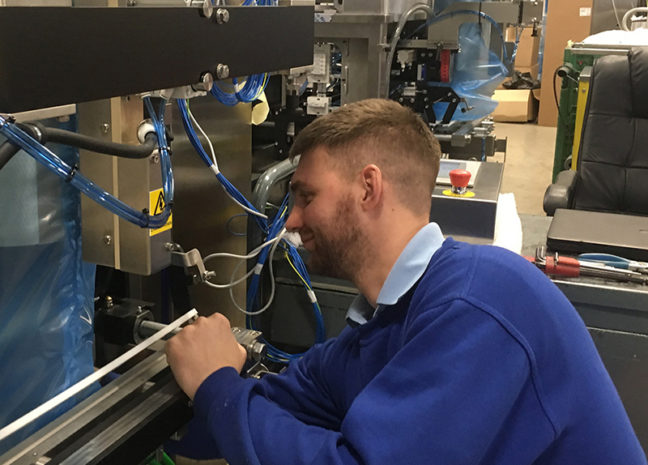

GIC has been designing, installing, and servicing vertical form fill and seal packaging machines for four decades. UK-made to the highest standards, GIC’s machines play an essential role in some of the country’s largest suppliers of frozen foods. GIC machines are designed and built in Gainsborough to exacting standards.

We are a gold-level partner in the Rockwell Automation PartnerNetwork™ programme, and all our component suppliers are hand-picked for quality and reliability.

Irrespective of whether you are packing roteins, frozen vegetables, chips or ice lollies, we can design a machine customised to your requirements. We back up our engineering excellence with operator training and comprehensive service and maintenance plans to ensure hassle-free ownership.

Our vertical form fill and seal machines offer the optimum combination of effectiveness, reliability and low cost of ownership backed by first class technical and servicing support.

Download Brochure

Key Considerations

If you’re considering introducing a new VFFS machine to your line, there are five key things to consider.

Packaging frozen foods presents a unique range of operational and engineering challenges. Equipment installed in these facilities must be carefully designed. It must be reliable and efficient yet easy to maintain and operate while withstanding low temperatures and complying with strict hygiene standards.

VFFS packaging machines operating in frozen food factories often require specially designed forming sets. When developing your machine, our team will consider the type of product, piece weight and size. IQF products can sometimes present problems where the wrapping material needs to be protected during the machine packaging cycle. Similar issues must also be addressed when specifying the product feed system, including a simple linear type weigher, servo volumetric filler, and multi-head weighers.

Not all packaging materials are suitable for use in a frozen food factory. Our machines are ideally suited to handle the frozen food sector’s packaging materials of choice: recyclable LDPE (polyethylene) materials, which offers high puncture resistance during distribution and in-store display, and high-performance laminate materials often used for premium product applications. Our VFFS machines can be specified with dual sealing systems to handle either type of material.

All GIC machines can be fully interfaced to a range of secondary packaging machinery, including cardboard box erectors, filling machinery, and plastic reusable crate systems. This end-of-line plant will also include check weighers, metal detection machinery and pallet loading equipment.

For the vertical seal, we can off er the TOSS HAS system continuous motion machines. This non-contact, low-maintenance system is ideally suited to working at high speeds in frozen food factories and is compatible with LDPE fi lm and other similar films.

For Frozen Foods

GIC 2100

- Maximum pack size250mm x 400mm

- Maximum speed90 packs per minute

- Pack formatsPillow, Gusset, Block Bottom, Euroslot, Quad

- Packaging materialsAll suitable heat-sealable materials, including laminates and polyethylenes. Optional impulse sealing

GIC 3100

- Maximum pack size250mm x 400mm

- Maximum speed160 packs per minute

- Pack formatsPillow, Gusset, Block Bottom, Euroslot, Quad

- Packaging materialsAll suitable heat-sealable materials, including laminates and polyethylenes. Optional impulse sealing

GIC 4100

- Maximum pack size400mm x 500mm

- Maximum speed60 packs per minute

- Pack formatsPillow, Gusset, Block Bottom, Euroslot, Quad

- Packaging materialsAll suitable heat-sealable materials, including laminates and polyethylenes. Optional impulse sealing

GIC 8100

- Maximum pack size400mm x 500mm

- Maximum speed160 packs per minute

- Pack formatsPillow, Gusset, Block Bottom, Quad, Doy

- Packaging materialsAll suitable heat-sealable materials, including laminates and polyethylenes. Optional impulse sealing

Free Site Appraisals

Irrespective of whether or not you currently rely on GIC vertical form fill and seal packaging machinery to keep your production line flowing efficiently, we offer free site appraisals.

Our experienced engineers will visit your facility and provide an accurate overview of the current condition of your packaging machinery, service and maintenance requirements, available software and hardware upgrades and opportunities to improve operating efficiency.

To request your free site appraisal, email us or call +44 (0) 1427 611885