Coffee

Coffee

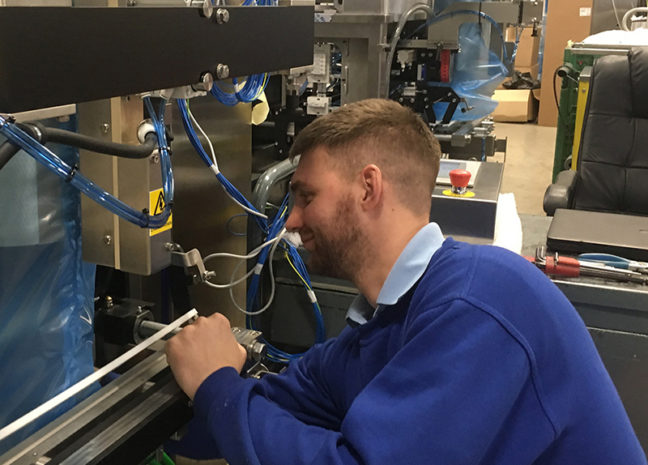

GIC has been designing, installing, and servicing vertical form fill and seal packaging machines for four decades. UK-made to the highest standards, GIC’s machines can play an essential role in the efficient packing of coffee beans and ground coffee.

GIC machines are designed and manufactured in Gainsborough to exacting standards. We are a gold-level partner in the Rockwell Automation Partner Network™ programme, and all our component suppliers are selected for quality and reliability.

We back up our engineering excellence with operator training and comprehensive service and maintenance plans to ensure low cost of overall ownership.

Our vertical form fill and seal machines offer the optimum combination of effectiveness, reliability and low cost of ownership, backed by first-class technical and servicing support.

Download Brochure

Key Considerations

If you’re considering introducing a new VFFS machine to your line, there are several things to consider.

How the coffee is presented to the vertical form fill and seal machine will affect both speed and finished pack weight accuracy. For optimal speed and accuracy with ground coffee, an auger filler is recommended; for coffee beans, a weighing system is optimal.

Whole beans and ground coffee are polar opposites in terms of packing. Whole beans flow easily, while ground coffee can be less free-flowing.

Ground coffee can produce a fine dust, which, if your vertical form fill and seal machine is not designed for the environment, can contaminate seals and sensors. Installing a dust extraction system or air-blow cleaning at the forming tube and sealing jaws might be needed to achieve the most efficient and reliable operation.

Depending on the infeed system, coffee beans can produce shavings as they move through the packing line. If this is the case and the beans are to be vacuum-loaded, we can modify the loader to minimise the volume of shavings.

Harsh drops at conveyor junctions can damage beans. Cushioning their fall, either by using lined weighers or installing slopes, can reduce the chances of damage.

It is essential to use high-barrier laminates, such as PET/AL/PE, metallised film, or kraft with barrier coating, to minimise oxygen, moisture, and aroma loss.

In terms of the seal, the inner layer – PE or PP – must be compatible with the sealing system, and coffee packaging often requires a film robust enough to hold the finished pack form and ensure a high-quality finished pack.

Some packaging materials now come with built-in degassing valves, eliminating the need for a valve application system.

Both freshly roasted beans and ground coffee release CO2 for several days. While ground coffee releases the gas more quickly, if the gas cannot escape, finished packs can swell or burst. One-way degreasing valves allow the gas to escape but will prevent oxygen ingress.

If the coffee bags are to be opened or used shortly after packing, a small hole in the bag may be sufficient, and a valve application system is not required.

Gas flushing, also known as Modified Atmosphere packaging (MAP), may be needed to extend the finished pack shelf life.

Both ground coffee and coffee beans are sold in the most common pack formats, such as pillow, gusseted, block bottom, and quad. They are also often produced with a one-way valve for degassing.

In many industries, speed is vital, and producers are looking to work as quickly as possible. However, coffee – particularly ground coffee – is delicate and seal integrity and weight accuracy are often more important than throughput speed and packs per minute.

It is essential that the vertical form fill and seal machines can work with the infeed roasters, grinders, weighers, and end-of-line packaging machinery.

For Ground Coffee & Coffee Beans

GIC 200

- Maximum pack size30 – 250mm

- Maximum speed50 packs per minute

- Pack formatsPillow, Gusset, Block Bottom, Euroslot, Carry Handle, Punch Hole

- Packaging materialsAll suitable heat-sealable materials, including laminates and polyethylenes. Can be adapted for paper.

GIC 400

- Maximum pack size400mm

- Maximum speed50 packs per minute

- Pack formatsPillow, Gusset, Block Bottom, Euroslot, Carry Handle, Punch Hole

- Packaging materialsAll suitable heat-sealable materials, including laminates and polyethylenes. Can be adapted for paper.

Free Site Appraisals

Irrespective of whether or not you currently rely on GIC vertical form fill and seal packaging machinery to keep your production line flowing efficiently, we offer free site appraisals.

Our experienced engineers will visit your facility and provide an accurate overview of the current condition of your packaging machinery, service and maintenance requirements, available software and hardware upgrades and opportunities to improve operating efficiency.

To request your free site appraisal, email us or call +44 (0) 1427 611885