GIC’S record year continues

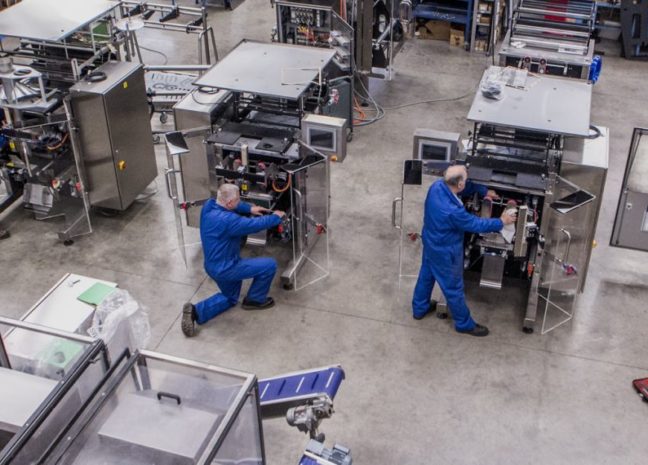

A Lincolnshire packaging machinery manufacturer’s excellent start to 2020 has continued this month, with the company sending a record number of machines out of the door.

In a typical month, GIC would see four of its vertical form fill and seal machines leave its Gainsborough factory. In June, the company delivered ten machines. All of the machines were supplied to UK food manufacturers.

2020 has been an excellent year so far for GIC, with orders in the first quarter being more than double year on year. May continued the upward trend for the company, with GIC receiving orders worth more than £3m, another record amount.

A new apprentice has been recruited this month, and further appointments could follow if business continues to increase.

“This year has been unlike any other,” says GIC managing director, Andy Beal. “The pandemic has seen a dramatic increase for UK-produced food, which has seen our customers packing more and more produce. As a result our customers have asked us to deliver machines as soon as possible. We’ve also seen new orders come in as food manufacturers increase their production capabilities.

“There is no doubt that the social distancing measures we have introduced have made manufacturing interesting but credit to our team, they’ve adapted to our new working practices really well, and we’ve been able to meet the increased demand.”

Last month, GIC increased its production area by 90 square metres by investing more than £30,000 in a new mezzanine floor, which is where the company’s electrical team are now based.

GIC was established in 1984, with its current directors – Andy Beal and Luke Murphy – assuming control of the business in 2006 through a management buy out.

“Despite the awful situation with the pandemic, we have seen enquiries and orders reach record levels,” says Andy. “We have won several prestigious, high-value contracts from both new and repeat customers. I think we are seeing the rewards from a lot of hard work from our sales team and also increased investment in marketing to get our name out there a bit more. I think we are also benefitting from the fact that our machines are exceptionally well built and we back that up with the best customer service and ongoing support that we can provide. Hopefully, the rest of 2020 will continue in the same vein.”

GIC offers an extensive range of vertical bagmakers, producing a wide range of finished bag sizes from 150 to 600mm wide, in both intermittent and continuous motion variants. All GIC machines offer low-cost ownership, robustness, reliability and exceptional build quality.

GIC’s machines integrate seamlessly with upstream equipment such as check-weighers, multi-head weighers, cup fillers and counters, with the company offering efficient and cost-effective after sales to all of its customers in fresh and frozen produce, cereals, snacks, confectionery, pasta, powders and pulses, industrial hardware and liquids.