GIC service team report record year

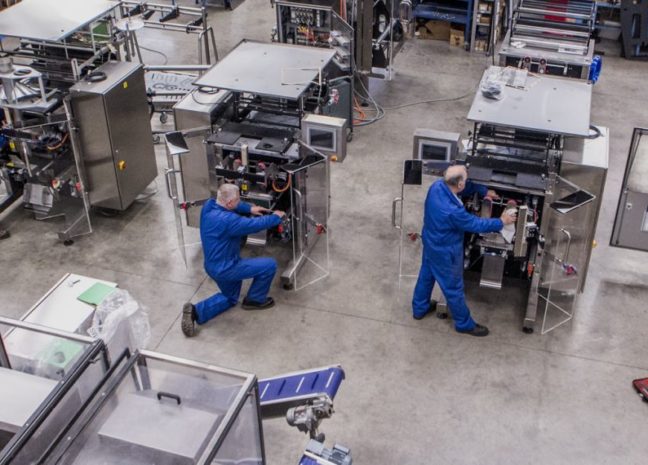

GIC, the leading designer and manufacturer of vertical form fill and seal packaging machinery, has reported a record year for its service team, with demand for after-sales support, servicing and spare parts growing by 60% since 2014.

A growing install base has helped drive demand for servicing and spares, but an increase in what GIC calls “Blue Chip” accounts, which have stringent audit trails for accreditations such as BRC, has also played its part says Andy Beal, GIC’s Managing Director.

“2019 was a very good year for GIC,” says Mr Beal. “We enjoyed increased demand for our machines and, with some customers now having nine or ten GIC machines on-site, we saw a dramatic increase in our service and maintenance offer. Recent years are also interesting as we saw an increase in demand for our higher specification more complex machines, which, in turn, leads to an increased role for GIC in helping our Customers maintain their machinery.

“In 2019, we installed more of our Leaf Salad Assisted Drop machines and machines which incorporated Ceetak’s Quick Pulse Heat (QPH) and the TOSS HLS hot air sealer systems,” continues Andy. “These are sophisticated and complicated machines, so it’s not surprising that our customers asked us to undertake servicing to ensure they stayed in tip-top condition.”

As well as undertaking on-site servicing and maintenance, GIC offers its customers telephone and technical support, through Simon Valentine, who is a dedicated Technical Support Manager based at the GIC factory.

“Simon joined us as Technical Support Manager in 2018, and as well as helping our customers with their enquiries, he has also played a valuable role in improving the documentation that our customers receive, which helps them maintain their machines on-site. In addition, many of our later machines have remote access facilities allowing Simon to diagnose faults from GIC,” adds Andy.

Based in Gainsborough, Lincolnshire, GIC was established in 1984. The company manufactures an extensive range of vertical bagmakers, producing a wide range of finished bag sizes from 150 to 600mm wide, in both intermittent and continuous motion variants. All GIC machines offer low-cost ownership, robustness, reliability and exceptional build quality.

GIC’s machines integrate seamlessly with upstream equipment such as check-weighers, multi-head weighers, cup fillers and counters, with the company offering efficient and cost-effective after sales to all of its customers in fresh and frozen produce, cereals, snacks, confectionery, pasta, powders and pulses, industrial hardware and liquids.