GIC 3100

Overview

The GIC3100 is ia high-speed constant motion servo machine best suited for gusseted, quad or doy pack formats where the product requires a high-care environment.

The GIC3100 can pack bag widths up to 250mm and incorporates robust, proven mechanical design and the latest Rockwell Allen Bradley maintenance-free servo technology to ensure industry-leading reliability and low cost of ownership.

Please contact GIC for further details.

Make an enquiry

Packaging a wide variety of products including:

-

COFFEE

COFFEE

- FRESH PRODUCE

- FROZEN FOODS

- HARDWARE

- PET FOOD

- POWDERS & PULSES

- PROTEIN

- SALAD & HERBS

- SNACKS & CONFECTIONERY

The GIC 3100 integrates seamlessly with

- Augers

- Check-weighers

- Multi-head weighers

- Pumps

- Cup fillers and counters

- All downstream equipment

Leading technology

Incorporates robust mechanical design with new counter balance system for higher speed application. Fitted with latest Allen Bradley platform. The result is industry leading reliability and low cost of ownership.

Specifications

- Maximum finished flat bag width250mm

- Maximum speed160 packs per minute

- Power supply3 phase supply – 415v 3ph + N and E. 25A per phase D rated

- Compressed airDependent on speed and application

- FinishBlack hard anodised aluminium and stainless steel

- Packaging materialsAll suitable heat sealable materials including laminates and polyethylenes (optional impulse sealing). Can be adapted for paper.

- Reel outer diameter450mm

- Reel core diameter76mm

- Weight1100kg

Pack Formats

-

Pillow

-

Block Bottom

-

Gusset

-

Quad

-

Doy

-

Zip

-

Euroslot

Standard

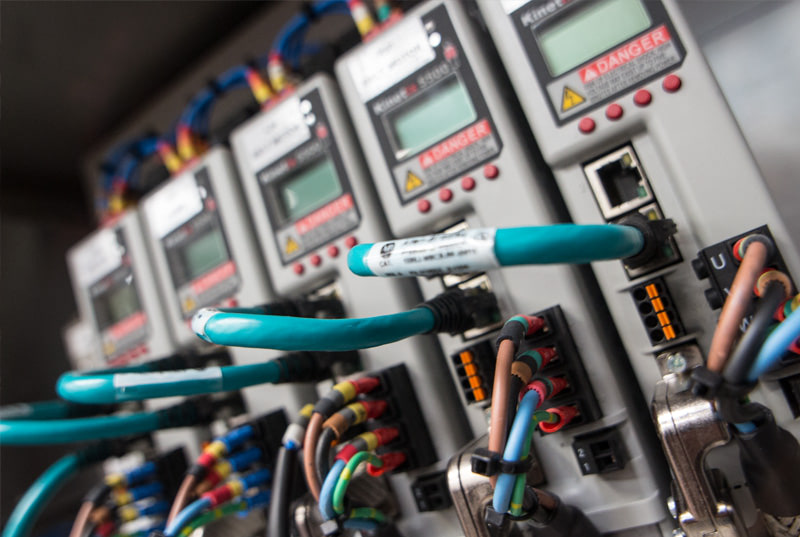

- Full maintenance-free Allen Bradley Kinetix 5500 Servo Drives x 5

- Allen Bradley Compact Logix PLC

- Full feature 10-inch colour Allen Bradley Panel view plus 7 1000 MMI touch screen

- Rotary Band back seal system

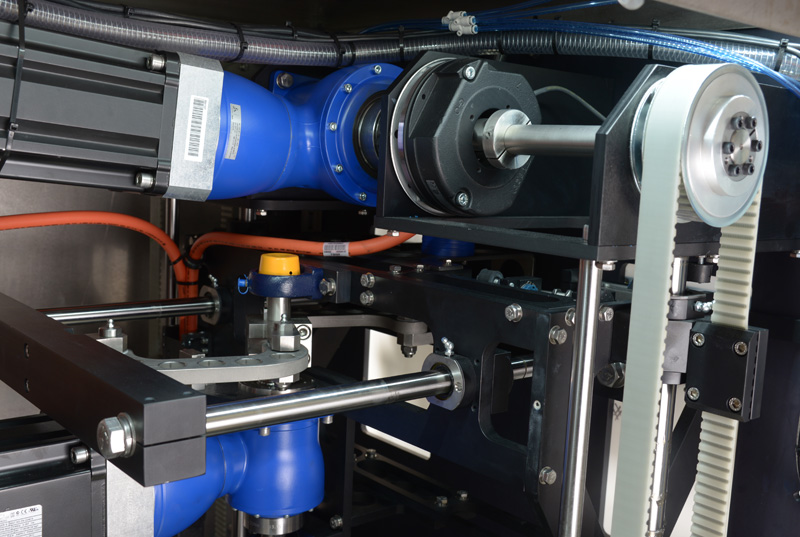

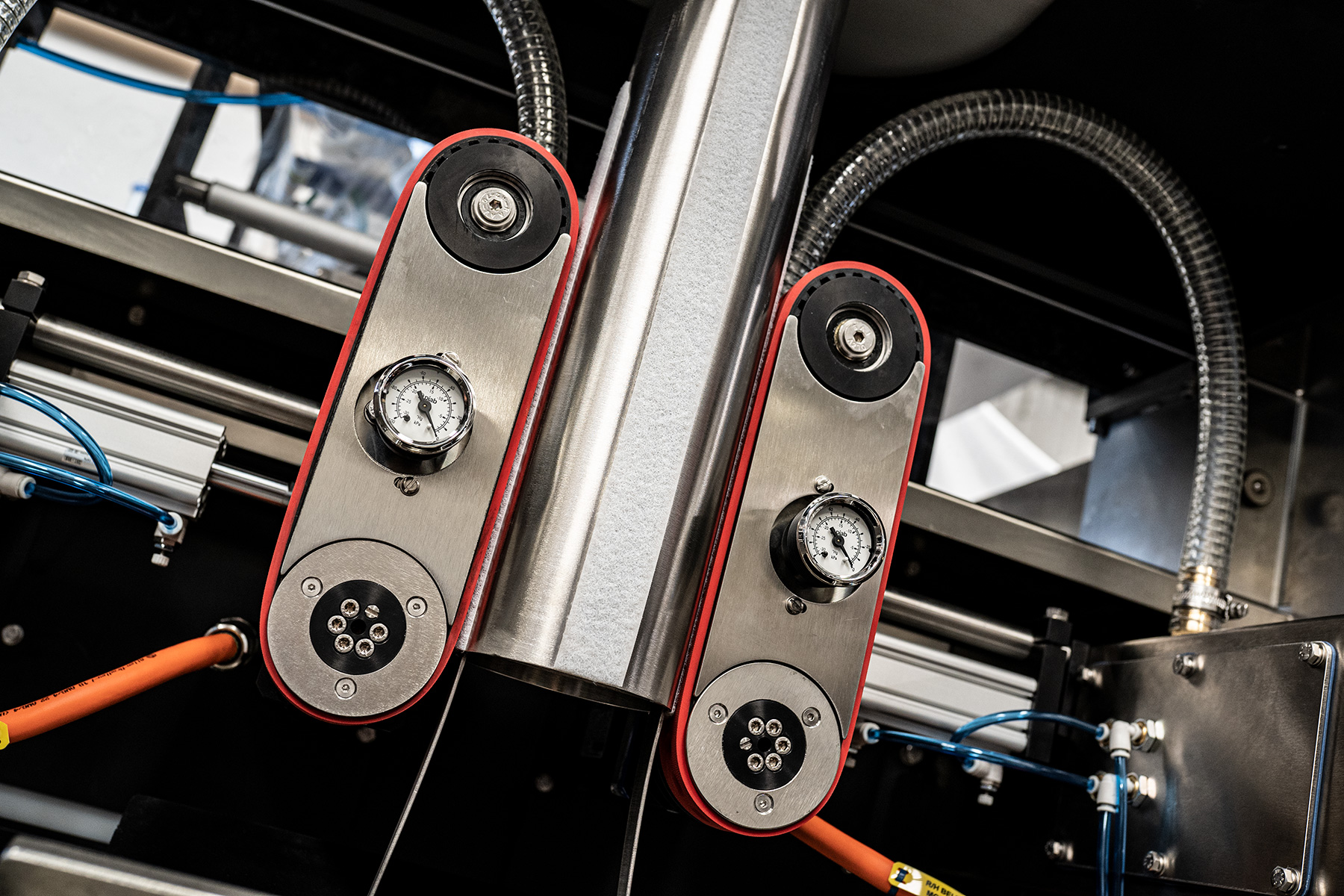

- Servo driven twin belt film transport with vacuum assist

- Drop on air mandrel. Allows for easy loading of film

- Hinged electrical enclosure for dual sided access

- Full SMC pneumatics with additional manifold capacity built in

- Pneumatic mechanical web tension control with electronic monitored actuation

- ‘High Care Environment’ specification as standard

- Reel run out sensor

- Manual film tracking incorporating coder and labeller

- Wrapper Print Registration (PEC)

- Provision for integrated Coder mounting and print roller

- Manual Splice Table with integrated tape dispenser

- Pack discharge chute

- PETG safety guards (10mm thick) complete with safety switches

Optional

- Continuous film feed mounted quad Sealing system

- Full servo driven automatic pack gusseting / block bottom

- Remote access

- Gas flushing

- Impulse poly-welding and alternative sealing systems

- Label application and print options

- Discharge elevator

- Pack turning device

- Carry bag handle application

The GIC 3100 Vertical Form Fill & Seal Machine

If you have a question, require further information or a quotation please don’t hesitate to contact us.