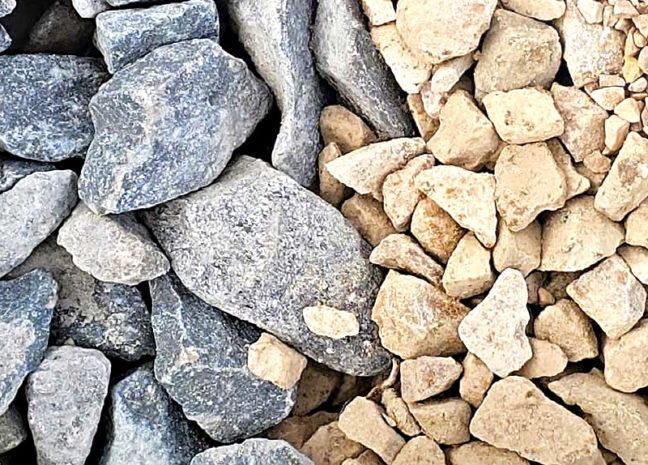

Aggregates

For Aggregates

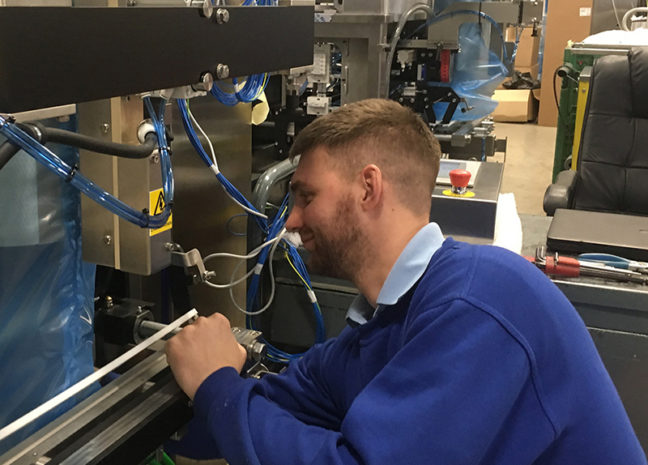

GIC has been designing, installing, and servicing vertical form fill and seal packaging machines for four decades. UK-made to the highest standards, GIC’s VFFS machines play an essential role in some of the country’s largest suppliers of aggregates.

GIC machines are designed and built in Gainsborough to exacting standards. We are a gold-level partner in the Rockwell Automation PartnerNetworkTM programme, and all our component suppliers are hand-picked for quality and reliability.

Irrespective of whether you are packing decorative aggregates, sand, gravel or slate, we can design a VFFS machine customised to your requirements. We back up our engineering excellence with operator training and comprehensive service and maintenance plans to ensure hassle-free ownership.

Our vertical form fill and seal machines offer the optimum combination of effectiveness, reliability and low cost of ownership backed by first class technical and servicing support.

Download Brochure

Key Considerations

When it comes to aggregates, the importance of packaging cannot be overstated. Getting the format and packaging right is essential.

If you’re an aggregates supplier considering upgrading your packaging machinery or investing in your first automated line, there are several things to consider.

The size and shape of the aggregate can affect its flow and overall packing efficiency. This will also determine the final weight of the product in each bag and influence the required strength of packaging material. Other issues occur such as fine aggregates requiring different handling compared to coarse aggregates.

The packaging material must be strong enough to hold the weight of the aggregates without tearing or puncturing. The packaging medium may require protection from the aggregates during the filling process.

Aggregates may be produced in many environments from quarries to indoor or outdoor production facilities, so your GIC machine will need to be built robustly to withstand these challenges.

For Aggregates

GIC 4100

- Maximum pack size400MM

- Maximum speed30 packs per minute

- Pack formatsPillow, Gusset, Block Bottom

- Packaging materialsAll suitable heat-sealable materials, including laminates and polyethylenes. Optional impulse sealing.

GIC 5100

- Maximum pack size500MM

- Maximum speed25 packs per minute

- Pack formatsPillow, Gusset

- Packaging materialsAll suitable heat-sealable materials, including laminates and polyethylenes. Optional impulse sealing.

Free Site Appraisals

Irrespective of whether or not you currently rely on GIC vertical form fill and seal packaging machinery to keep your production line flowing efficiently, we offer free site appraisals.

Our experienced engineers will visit your facility and provide an accurate overview of the current condition of your packaging machinery, service and maintenance requirements, available software and hardware upgrades and opportunities to improve operating efficiency.

To request your free site appraisal, email us or call +44 (0) 1427 611885