VFFS Machinery for Fresh Produce

Fresh Produce

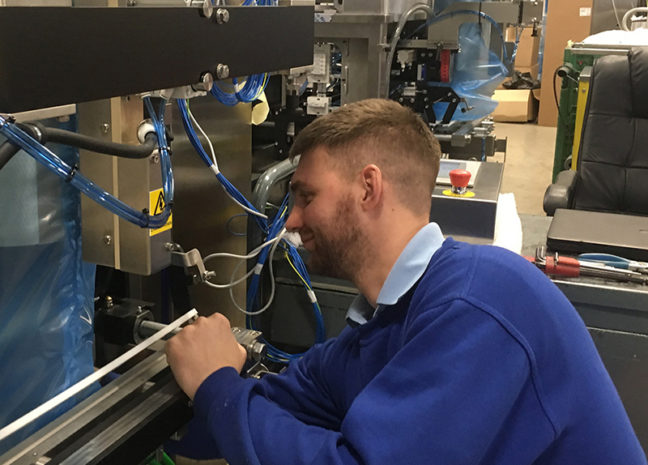

GIC has been designing, installing, and servicing vertical form fill and seal packaging machines for four decades. UK-made to the highest standards, GIC’s machines play an essential role in some of the country’s largest suppliers of fresh produce. GIC machines are designed and built in Gainsborough to exacting standards.

We are a gold-level partner in the Rockwell Automation PartnerNetwork™ programme, and all our component suppliers are hand-picked for quality and reliability.

Irrespective of whether you are packing potatoes, carrots, onions, sweet potatoes, bean sprouts, prepared veg or other fresh produce, we can design a machine customised to your requirements. We back up our engineering excellence with operator training and comprehensive service and maintenance plans to ensure hassle-free ownership.

Our vertical form fill and seal machines offer the optimum combination of effectiveness, reliability and low cost of ownership backed by first class technical and servicing support.

Download Brochure

Key Considerations

When packing fresh produce with a GIC vertical form fill and seal (VFFS) machine, several factors need to be considered to ensure efficient and effective packaging:

For any packaging machine and, in fact any production line to work effectively, you need a consistent feed of your product. Knowing how effectively the produce will be presented to the vertical form fill and seal packaging machine will determine whether a continuous motion or intermittent machine is best suited.

No one wants to find damaged or bruised produce in their pack when they get home, so it is crucial for the packaging line to handle the produce gently at speed. For example, GIC provide an angled solution for delicate products such as sweet potatoes.

The weight of finished packs can vary dramatically, from 50g to 10kg. Knowing if the machine will be packing large or small produce, or a mixture of weights and sizes will allow us to supply the correct machine, forming set and tooling design.

The type of packaging, from paper to 20mμ mono plastic film, will also influence the type of packaging machine required.

We design our machines to be very easy to service, maintain, and operate. Downtime is critical, and factories and packhouses with large volumes demand quick changeovers if moving from one SKU to another. We have over 35 years of experience to draw upon, which is evident in our extensive U.K. install base.

For Fresh Produce Producers

GIC CUB

- Maximum pack size150mm

- Maximum speed60 packs per minute

- Pack formatsPillow, Gusset, Block Bottom

- Packaging materialsAll suitable heat-sealable materials, including laminates and polyethylenes. Optional impulse sealing

GIC 200

- Maximum pack size30 – 250mm

- Maximum speed50 packs per minute

- Pack formatsPillow, Gusset, Block Bottom, Euroslot, Carry Handle, Punch Hole

- Packaging materialsAll suitable heat-sealable materials, including laminates and polyethylenes. Can be adapted for paper.

GIC 400

- Maximum pack size400mm

- Maximum speed50 packs per minute

- Pack formatsPillow, Gusset, Block Bottom, Euroslot, Carry Handle, Punch Hole

- Packaging materialsAll suitable heat-sealable materials, including laminates and polyethylenes. Can be adapted for paper.

GIC 2100 – Intermittent variants

- Maximum pack size250mm

- Maximum speed90 packs per minute

- Pack formatsPillow, Gusset, Block Bottom

- Packaging materialsAll suitable heat-sealable materials, including laminates and polyethylenes. Optional impulse sealing

GIC 3000 – Continuous Motion Variants

- Maximum pack size250mm

- Maximum speed100 packs per minute

- Pack formatsPillow, Gusset, Block Bottom

- Packaging materialsAll suitable heat-sealable materials, including laminates and polyethylenes. Optional impulse sealing

GIC 3100 – Continuous Motion Variants

- Maximum pack size400mm

- Maximum speed150 packs per minute

- Pack formatsPillow, Gusset, Block Bottom, Quad, Doy

- Packaging materialsAll suitable heat-sealable materials, including laminates and polyethylenes. Optional impulse sealing

GIC 4100 – Intermittent variants

- Maximum pack size400mm

- Maximum speed90 packs per minute

- Pack formatsPillow, Gusset, Block Bottom

- Packaging materialsAll suitable heat-sealable materials, including laminates and polyethylenes. Optional impulse sealing

GIC 8000 – Continuous Motion Variants

- Maximum pack size400mm

- Maximum speed100 packs per minute

- Pack formatsPillow, Gusset, Block Bottom

- Packaging materialsAll suitable heat-sealable materials, including laminates and polyethylenes. Optional impulse sealing

GIC 8100 – Continuous Motion Variants

- Maximum pack size400mm

- Maximum speed150 packs per minute

- Pack formatsPillow, Gusset, Block Bottom, Quad, Doy

- Packaging materialsAll suitable heat-sealable materials, including laminates and polyethylenes. Optional impulse sealing

Free Site Appraisals

Irrespective of whether or not you currently rely on GIC vertical form fill and seal packaging machinery to keep your production line flowing efficiently, we offer free site appraisals.

Our experienced engineers will visit your facility and provide an accurate overview of the current condition of your packaging machinery, service and maintenance requirements, available software and hardware upgrades and opportunities to improve operating efficiency.

To request your free site appraisal, email us or call +44 (0) 1427 611885