Fresh Leaf Salad & Herbs

For Fresh Leaf Salad & Herb Producers

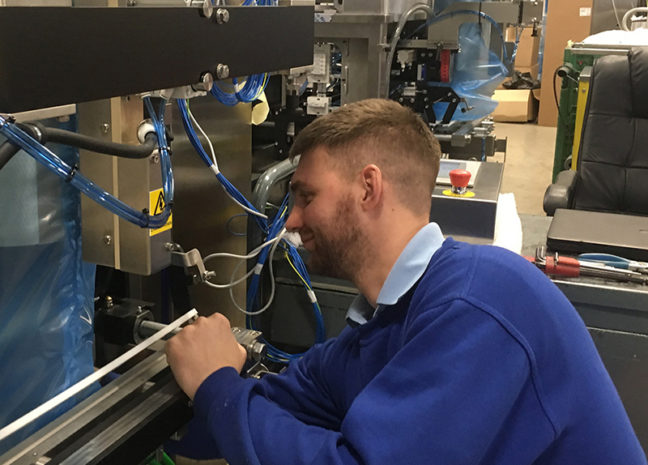

GIC has been designing, installing, and servicing vertical form fill and seal packaging machines for four decades. UK-made to the highest standards, GIC’s machines play an essential role in some of the country’s largest confectionery producers.

GIC machines are designed and built in Gainsborough to exacting standards. We are a gold-level partner in the Rockwell Automation PartnerNetworkTM programme, and all our component suppliers are hand-picked for quality and reliability.

Irrespective of whether you are packing loose leaf salads or any variety of herb, we can design a machine customised to your individual requirements. We back up our engineering excellence with operator training and comprehensive service and maintenance plans to ensure hassle-free ownership.

Our vertical form fill and seal machines offer the optimum combination of effectiveness, reliability and low cost of ownership backed by first class technical and servicing support.

Download Brochure

Key Considerations

When it comes to salad & herbs, the importance of packaging cannot be overstated. Getting the format and packaging rightis essential.

If you’re a growing salad & herbs supplier considering upgrading your packaging machinery or investing in your first automated line, there are several things to consider.

Packaging leaf salad and herbs presents a unique range of operational and engineering challenges. From specifying the correct machinery to handle a range of temperature and humidity issues to achieving the optimal conditions for handling delicate leaves, GIC can develop a packaging solution for this market sector.

VFFS packaging machines operating in salad and herb factories often require specially designed forming sets. When developing your machine, our team will consider the fragility of the produce, the uniformity of the leaf size and shape, the desired weight and pack type.

Not all packaging materials are suitable for use in a salad or herb factory. Our machines are ideally suited to handle the fresh produce sector’s packaging materials of choice. Our VFFS machines can be specified with dual sealing systems to handle multiple types of material.

All GIC machines can be fully interfaced to a range of upstream filling systems and end-of-line plant including check weighers, metal detection machinery and pallet loading equipment.

GIC’s exclusive Leaf Salad Assisted Drop functionality integrates seamlessly with the company’s VFFS machines, increasing bagging speeds and reducing film usage, contamination levels and re-work.

Leaf Salad Assisted Drop creates an area of low pressure in the product chute, drawing salad leaves into the bag in one single slug, thereby eliminating upstream choking. Without this functionality, the product mass elongates into several clumps of salad leaf, which increases the chances of causing contamination by being captured in the seal. Leaf Salad Assisted Drop also allows packers to reduce their film use, by reducing bag size, something consumers are currently keen to see.

As well featuring on new GIC machines, we can also retrofit Leaf Salad Assisted Drop functionality, to deliver up to a 10% increase in productivity and vastly reduced seal contamination levels and downtime.

For Fresh Leaf Salad & Herbs

GIC 2100

- Maximum pack size250mm

- Maximum speed70 packs per minute

- Pack formatsPillow, Gusset, Block Bottom

- Packaging materialsAll suitable heat-sealable materials, including laminates and polyethylenes. Optional impulse sealing.

GIC 3000

- Maximum pack size250mm

- Maximum speed100 packs per minute

- Pack formatsPillow, Gusset, Block Bottom

- Packaging materialsAll suitable heat-sealable materials, including laminates and polyethylenes. Optional impulse sealing.

GIC 3100

- Maximum pack size400mm

- Maximum speed150 packs per minute

- Pack formatsPillow, Gusset, Block Bottom, Quad, Doy

- Packaging materialsAll suitable heat-sealable materials, including laminates and polyethylenes. Optional impulse sealing.

GIC 4100

- Maximum pack size400mm

- Maximum speed30 packs per minute

- Pack formatsPillow, Gusset, Block Bottom

- Packaging materialsAll suitable heat-sealable materials, including laminates and polyethylenes. Optional impulse sealing.

GIC 8000

- Maximum pack size400mm

- Maximum speed100 packs per minute

- Pack formatsPillow, Gusset, Block Bottom

- Packaging materialsAll suitable heat-sealable materials, including laminates and polyethylenes. Optional impulse sealing.

GIC 8100

- Maximum pack size400mm x 500mm

- Maximum speed160 packs per minute

- Pack formatsPillow, Gusset, Block Bottom, Quad, Doy

- Packaging materialsAll suitable heat-sealable materials, including laminates and polyethylenes. Optional impulse sealing.

Free Site Appraisals

Irrespective of whether or not you currently rely on GIC vertical form fill and seal packaging machinery to keep your production line flowing efficiently, we offer free site appraisals.

Our experienced engineers will visit your facility and provide an accurate overview of the current condition of your packaging machinery, service and maintenance requirements, available software and hardware upgrades and opportunities to improve operating efficiency.

To request your free site appraisal, email us or call +44 (0) 1427 611885